AlfaFlash ZLD systems for the manufacturing industry

Manufacturing processes requires large amounts of water. This results in higher costs for treatment, disposal and the purchasing of water. Additionally, increasing legislation is making the demands on how this water is to be disposed of more difficult. Efficient treatment of the wastewater through evaporation not only separates residual solids and chemicals which may be present also, the resulting distillate water can be reused. The AlfaFlash ZLD system treat this wastewater to remove these items, making the remaining waste easier and less expensive to dispose of.

The AlfaFlash ZLD system delivers benefits to the manufacturing industry:

- Effectively eliminates manufacturing wastewater reducing transport, treatment, and disposal costs

- Recycle water for reuse

- Contribute to achieving environmental requirements and sustainability goals

- Recover chemicals from the wastewater for reuse

- Flexible system for different waste streams and growth as your needs change

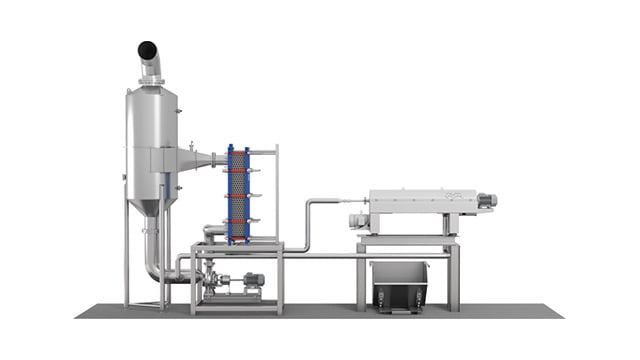

The AlfaFlash ZLD systems

The need to reduce water usage is getting greater. The AlfaFlash ZLD system can contribute to meeting this need. For example, a service centre with a 1% solids concentration in the wastewater, the AlfaFlash ZLD system provided up to 99% water recovery. Effective evaporation of manufacturing wastewater often can achieve the goals you are looking for and create a minimal liquid by-product.

The most important machine here is the AlfaFlash ZLD from Alfa Laval. The AlfaFlash takes in the wastewater from the cleaning baths, for which we have no alternative treatment. Also, the AlfaFlash can handle variations in the wastewater really well and gives us back more than 99% of the wastewater as reusable distillate water, reducing our freshwater costs and footprint

Sometimes, however, the need to reduce the liquid in the by-product even further is required. By adding a decanter centrifuge to your evaporation solution, you can reduce the water in the solids even more. Other advantages in adding this step to the process is that you can then even further separate chemicals and materials, either for reuse, or to make the waste even easier to transport, treat and dispose of.

AlfaFlash ZLD system without decanter centrifuge

AlfaFlash ZLD system with decanter centrifuge

Industries that can benefit from the AlfaFlash ZLD system

Industries below produce wastewater which can include elements such as metal salts and, organic substances in dissolved or suspended form:

- Metal treatment

- Service centres

- Automotive

- Power equipment

- Aluminium can production

- Aerospace

- Textile/tanneries

- Electronics

- Semi-conductor

It’s critical that the equipment chosen to treat this wastewater in these industries can handle the high demands to effectively separate varied waste. Equipment such as the AlfaFlash ZLD system meet or exceed these demands, often at lower lifetime operating costs than other technologies. The flexibility of the AlfaFlash ZLD system not only allows for it to handle different waste flows, it can also expand and change as the needs of your business do.

An example of applications where the AlfaFlash ZLD system can reduce wastewater costs:

- Machining and surface treatment wastewaters

- Plating rinse water

- Treatment bath bleed-off stream

- Wash water

- Cleaning-in-place (CIP) liquids

- RO reject streams

- Waste/spent caustic in leaching processes

Alfa Laval opens state-of-the-art service centre that recycles almost 100 percent of its water

Alfa Laval's new service centre in Frechen, Germany, will be one of the largest for plate heat exchangers in the world. In addition, it is also a technically advanced and sustainable facility, capable of recycling almost 100 percent of its water using Alfa Laval AlfaFlash ZLD technology.