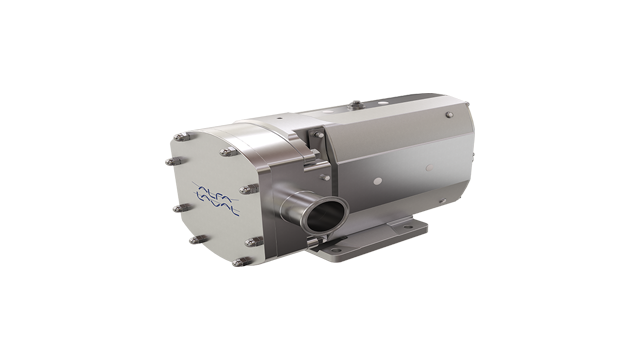

SX

The Alfa Laval SX Rotary Lobe Pump is designed with optimized pump head geometry and multi-lobe rotors to ensure low-shear operation with minimum pulsation. This makes the SX the best choice for maintaining the integrity of delicate products. The pump is designed according to the most stringent hygienic design standards and with verified, effective Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP).

Premium rotary lobe pump designed for gentle transportation of process fluids in hygienic and ultra-clean applications

- Low pulsation and very gentle pumping, making the pump ideal for sensitive products.

- Minimized shearing for protecting end-product quality

- Low maintenance, increased process uptime

- Maximized performance and minimized risk of contamination.

The SX Rotary Lobe pump is designed for gentle transportation of process fluids in hygienic and ultra-clean

applications in the biotechnology and pharmaceutical industries, in the home and personal care sector, and for

demanding food applications. The SX Rotary Lobe Pump is available with 14 different pump head displacements based on seven different gearbox modules to handle flow rates up to 115 m3/h and differential pressures up to 15 bar.

Best choice for transporting

With the SXs multi-lobe rotor geometry it offers low pulsation and gentle pumping. This makes it the best choice for transporting sensitive products that require gentle handling to minimize shearing. This EHEDG-approved pump is designed for both Cleaning in Place and Sterilization in Place.

Protecting end-product quality

Low pulsation, low shear and low noise characteristics, while ensuring efficient fluid transfer, are trademarks for the SX pump. This high level of performance has been achieved through a detailed understanding of flows and the exact geometry of the rotors and rotor case. For this Alfa Laval employs Computational Fluid Dynamics (CFD).

Enhanced cleanability

SX rotary lobe pumps are designed with features that maximize performance and minimize the risk of contamination. These include a low-profile rotor nut, hygienic front-loading mechanical seals, defined compression front cover sealing, fully drainable pump head with 3° fall angle, and sanitary or ultra-clean surface finishes.

Cleanability hand-in-hand with low maintenance

Designed for maximum cleanability and ease of access, the SX pump is a low maintenance solution. Alfa Laval manufactures all pump parts, including the rotor case and high-precision rotors. This facilitates maintenance and guarantees full interchangeability of spare rotor parts.

For reliable operation and lower maintenance the robust gearbox construction comes with heavy-duty shafts, torque locking assemblies and taper roller bearings throughout. The gearbox’s universal design provides the flexibility of mounting the pumps with inlet and outlet ports in vertical or horizontal position.

Supply and delivery

Available in 14 different models, SX rotary lobe pumps are capable of handling of a wide variety of viscosity and temperature requirements, flow rates up to 115 m3/h, pressures up to 15 bar and temperatures up to 150°C. A wide range of seals is available to ensure that the right seal is selected for the specific application.

Certification, specification and standards

All SX rotary lobe pumps comply with EHEDG, 3-A, 3.1 and FDA hygienic standards and have ATEX approval for use in explosive environments. For more information, please consult the documentation provided.

SX Rotary lobe pump - Exploded

Product Benefits

- Low pulsation and gentle pumping

- Minimize shearing

- Maximize performance and minimize the risk of contamination

Як це працює

Construction

Alfa Laval rotary lobe pumps are conventional positive displacement pumps with rotor case, rotor case cover, rotors, rotor nuts, shafts, gearbox, shaft seals and elastomers. The pumps operate with no internal contacting parts in the pump head.

The SX can be supplied either as a bare shaft pump or mounted on a base plate complete with coupling, guard, gear motor and shroud for easy plug-and-play installation.

The standard materials of construction are 316L stainless steel for all wetted parts and painted cast iron for the gearbox. Other materials are available on request.

In addition, Alfa Laval manufactures all pump parts, including the rotor case and high-precision rotors. This facilitates maintenance and guarantees full interchangeability of spare rotor parts.

Operating principle

A gear train in the pump gearbox drives the rotors and provides accurate synchronization, or timing, of the rotors. The contra-rotating propulsion system has two rotors spinning in opposite directions within the pump head. Fluid is carried through the pump in the cavities formed between the dwell of the rotor and the interior of the rotor case.

Зручний моніторинг технічного стану насосів, що відповідають гігієнічним вимогам

Моніторинг технічного стану Alfa Laval CM контролює робочий стан обертового обладнання, наприклад насосів.

Part of a broad pump range

Alfa Laval offers a comprehensive range of pumps intended for hygienic applications in the dairy, food, beverage, home care, personal care, biotechnology and pharmaceuticals.

For a broader pump range, explore the different product categories: Centrifugal pumps, Circumferential piston pumps and Twin Screw.

Харчова логіка

Гігієнічне обладнання Alfa Laval поєднує в собі високу продуктивність та акуратне поводження, щоб зберегти чутливі інгредієнти та не відставати від тенденцій харчової промисловості. Обладнання вирішує чотири ключові проблеми; постачання харчових продуктів споживачам за конкурентоспроможною ціною, отримання максимуму від сировини, зменшення відходів та викидів, а також доставка безпечних та гігієнічних харчових продуктів.

Онлайн-каталог "Close at hand"

Каталог компонентів та рішень Альфа Лаваль для гігієнічного обладнання

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.