GJ

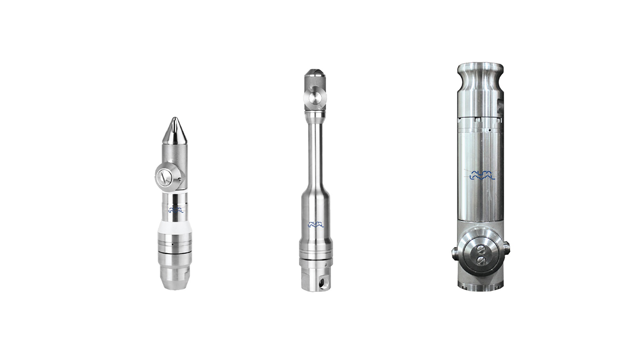

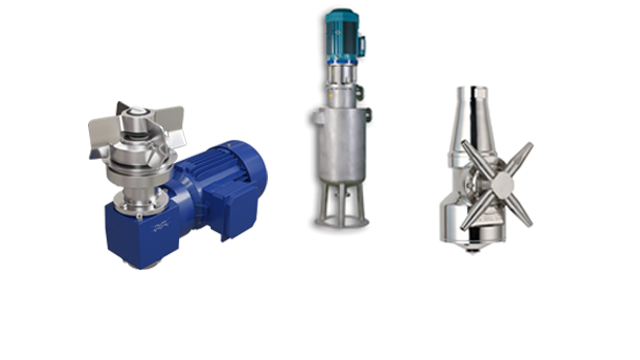

The Alfa Laval GJ product line offers a wide range of tank cleaning machines for industrial applications, such as paint, steel, pulp & paper, chemicals, and oil & gas. The range spans from being able to clean small storage/process tanks to the big industrial fermenters and storage tanks of sizes more than 5678m3 (1.5 million gallons). The line also includes a special unit to clean underground storage tanks through one way opening.

A quality product

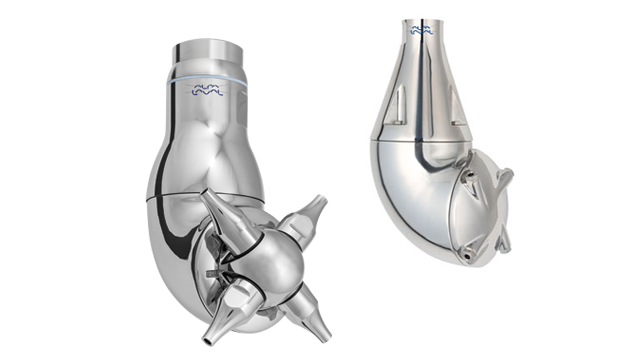

The Alfa Laval GJ tank cleaning devices are part of our highly acclaimed Gamajet product range. Alfa Laval technology combines pressure and flow to create high impact cleaning jets that are precision engineered to rotate in a precise, repeatable and reliable 360-degree pattern.

Positive return on investment

The unique design reduces your cost to clean and environmental footprint by minimizing the amount of water, energy and cleaning agents required to clean tanks. Using high-impact jet cleaning instead of traditional ineffective static spray ball reduces waste and resource consumption.

Retrofit old spray ball

Due to the physical size of the Alfa Laval GJ PF, it is now possible to upgrade your cleaning device to a more efficient solution. The low profile Alfa Laval GJ PF fits though a 4” connection, making it possible to install the device into an existing tank top connection.

Product benefits

- Fast cleaning time = More production time.

- Reduces water and resource usage, leading to reduced cost to clean.

- Eliminates the need for confined space entry for manual tank cleaning.

- Durable and reliable, rotary jet heads are proven to boost cleaning efficiency by providing reliable and repeatable cleaning performance.

- Cleaning process can be validated using Alfa Laval RotaCheck

Як це працює

High-impact, low-resource cleaning

The high-impact jet stream from the rotary jet head is preprogrammed to cover the inside of the tank in a continually denser pattern. This achieves a powerful mechanical impact with a low volume of water, acid or caustic. Most of the GJ rotary jet heads are capable of operating at both high and low pressures.

Smoother, long-lasting performance

The Alfa Laval GJ range includes a unique, grease-lubricated gear to ensure that potentially damaging particles are not trapped in the gear during CIP recirculation. This innovative design ensures a smoother performance and reduces wear and tear.

Energy-efficient design

A faster tank cleaning cycle also cuts energy consumption. Cleaning fluid flows through the nozzles in an automated, geared rotation around the vertical and horizontal axes. In the first cycle, the nozzles lay out a coarse pattern on the tank surface, with subsequent cycles progressively densifying the pattern over the course of eight cycles.

You may also be interested in…

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

360° Service Portfolio

Alfa Laval hygienic equipment is backed by the Alfa Laval 360° Service Portfolio to extend performance.