Sani SB

The Alfa Laval Sani SB is a rotary spray head tank cleaning machine for hygienic environments. The Alfa Laval Sani SB minimizes the consumption of water and cleaning media. Easy to customize to meet customer requirements, the Sani SB allows companies to spend less time cleaning and more time producing. The Sani SB is authorized to carry the 3-A symbol.

Exceptional cleanability, better end-product quality, greater overall output and reduced operating cost

- 40% faster cleaning, meaning more time for production

- Saves up to 40% of your cleaning cost

- Dynamic cleaning performance and 360° full wetting

- Easy to retrofit traditional spray balls to a more economical

The Alfa Laval Sani SB is designed for the removal of residues from hygienic tanks across the dairy, brewery, distillery, beverage, food, personal care and biotech and pharmaceutical industries.

Cost-effective cleaning

When higher cleaning efficiency than that offered by static spray balls is required, it is easy to upgrade to Toftejorg rotary spray head technology. Simply unclip the static spray ball and replace it with a new clip-on rotary spray head.

As the spray head rotates, its fans produce a variable falling film, which has higher heat and mass transfer coefficients than the falling film produced by the static spray ball. This enables the optimization of cleaning procedures and significant savings on water, chemicals and energy.

Efficient residue removal

To achieve the best cleaning results, Toftejorg rotary spray heads use a spray pattern to ensure the dynamic and effective distribution of rinse water to the inner tank surfaces. The impact from the rotating fans and improved mass and heat transfer provide efficient residue removal after production.

Self-draining and self-cleaning, inside and out, all Toftejorg rotary spray head devices comply with Good Manufacturing Practice.

An economic and environmentally correct choice

With perfectly flushed bearings and crevice-free design, Toftejorg rotary spray heads effectively clean tanks using less water, less energy and less cleaning agents than static spray balls. This not only helps reduce consumption of high-purity water and chemicals, but boosts your company’s environmental profile.

Performance reliability and long service life

Designed with minimal internal pressure loss, Toftejorg rotary spray heads rotate at pressures of less than 0.1 bar; however, the recommended operating pressure is between 2 and 3 bars. For over half a century, rotary spray head technology has proven successful in providing reliable and repeatable cleaning performance and a long service life.

Low maintenance, minimal downtime

Generally speaking, routine inspection is the only maintenance required for Toftejorg rotary spray head devices. These devices are so reliable that a single device in many cases can meet the requirements of a plant over its entire lifetime. No spare parts are likely to be needed for these devices.

High product integrity

To ensure product integrity, all Toftejorg rotary spray head devices are made of safe and non-reactive hygienic materials. All materials made of stainless steel are fully traceable in accordance EC No. 1935/2004. All non-metallic parts used comply with FDA requirements 21CFR § 174; non-metallic parts of rotary spray heads used for the Biopharm applications are certified in accordance with USP Class VI regulations. Upon request, 3.1 certificates can be supplied for those tank cleaning devices that meet the EN10204 standard. The Rotary jet head is also 3A certified.

Total peace of mind with complete documentation for validation

All equipment and components in the Alfa Laval BioPharm portfolio can be supplied with Alfa Laval Q-doc, a comprehensive documentation package that provides full transparency of sourcing, production and supply chains as well as full traceability of all changes in material, manufacturing procedures or spare parts. This smoothes process validation by providing factual support to substantiate GDP (Good Documentation Practice) for every aspect of BioPharm equipment supply and provides customers with high-quality Alfa Laval products backed by a no-risk guarantee.

The Q-doc package comprises equipment manuals, product/performance test, quality and manufacturing procedures, relevant material certificates, traceability documentation, and the necessary parts and service information. This attention to detail maximizes uptime and minimizes risk.

Product benefits

- 40% faster cleaning = more time for production

- Dynamic cleaning performance and 360° full wetting

- Saves up 40% of your cleaning cost

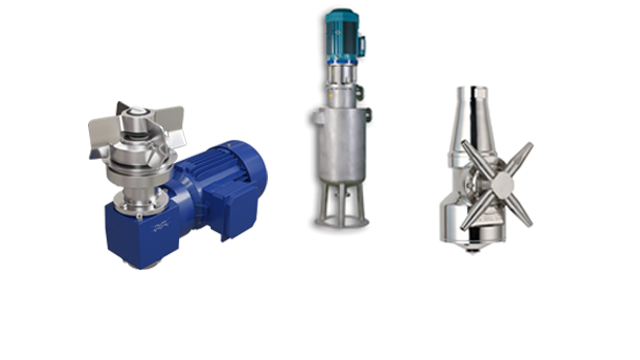

The range of Sani SB:

Cleans with a rotating fan generating impact and coverage. This results in lower liquid consumption and in shorter time.

Як це працює

Toftejorg rotary spray heads use the cleaning fluid itself to provide coverage and impact. The physical flow of the cleaning media causes the rotary spray head to rotate, with fans laying out a swirling pattern across the inner surface of the vessel.

These fans provide a combination of physical impact and a variable falling film of cleaning fluid that covers all the internal surfaces of the tank or reactor. The variable falling film has higher heat and mass transfer coefficients than the falling film produced by the static spray ball.

The spray head also cleans itself by directing the cleaning media through the rotating bearing track and onto the neck of the elongated head.

Rotary spray heads are a cost-effective alternative to traditional static spray balls because they use only small volumes of cleaning fluid at low pressure.

These devices are suitable for virtually all kinds of industrial cleaning, including tanks, reactors, vessels and other containers.

Part of a broad tank equipment range

Alfa Laval offers a comprehensive range of tank equipment intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

For a broader tank equipment range, explorer the different product categories: rotary jet heads, rotary spray heads, tank accessories and tank covers.

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

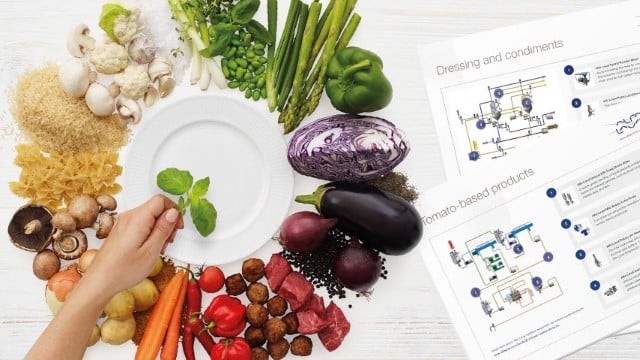

Харчова логіка

Гігієнічне обладнання Alfa Laval поєднує в собі високу продуктивність та акуратне поводження, щоб зберегти чутливі інгредієнти та не відставати від тенденцій харчової промисловості. Обладнання вирішує чотири ключові проблеми; постачання харчових продуктів споживачам за конкурентоспроможною ціною, отримання максимуму від сировини, зменшення відходів та викидів, а також доставка безпечних та гігієнічних харчових продуктів.

Онлайн-каталог "Close at hand"

Каталог компонентів та рішень Альфа Лаваль для гігієнічного обладнання

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.