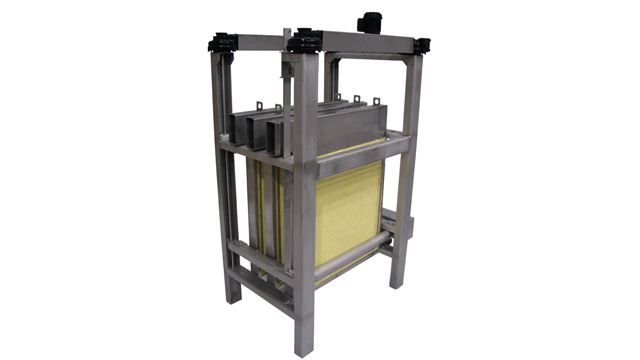

AS-H Iso-Disc

The high-performance cloth media filter captures solids to produce reuse-quality filtrate in a continuous operating process. The polishing filter is designed for tertiary filtration and final polishing in municipal and industrial wastewater treatment.

Simple, efficient and flexible solution to your wastewater filtration requirement

- High-quality filtrate with California Title 22 Water Reuse Certification

- Easy to operate with fully automatic filtration and uninterrupted operation during backwashing cycle

- Easy to maintain due to individual filter element monitoring and maintenance

- Small footprint-to-flow ratio

- Robust design

The Alfa Laval Iso-Disc wastewater filter is designed to fit your specific needs flexibly. The wastewater system can be easily expanded. Both square and rectangular cassettes fit within the path of the incoming water and are available to cater different installation configurations. It also allows for individual visual assessment of the effluent flow rate and quality.

How does the cloth media filter work

Use of the fixed-filter media design reduces overall horsepower and permits removal of each individual filter plate while the filter remains in operation. During backwash, the filter plates remain fixed while the dynamic, bi-directional, linear backwash manifold serves as a header for removal of solids from the pile cloth media.

At the beginning of the backwash cycle, which is initiated by headloss across the filter, electrically actuated valves segregate the backwash header and clean the filter plates on that portion of the header. This ensures complete cleaning of the filter cloth while minimizing the rate at which backwash water is returned to the treatment facility.

The Iso-Disc cloth media filter can be installed into a concrete structure (supplied by others), pre-fabricated carbon steel with epoxy coating, or stainless steel tanks.

A unique advantage is incorporated into the Iso-Disc design that allows filtrate isolation and sampling from each filter plate individually, as well the ability to remove an entire filter plate from the system without filter shutdown. The design also eliminates rotating underwater seals thereby ensuring filtrate quality, while guaranteeing no cross-connection between influent and filtrate, and requiring less maintenance.

Top performance

Performance of the Iso-Disc cloth media filter is second to none. The cloth media is capable of solids capture down to less than 10 microns. The pile cloth media allows for complete cleaning during backwash, utilizing filtered water from inside the filter plate. If required, the cloth media can be replaced and the filter plate re-installed in a matter of minutes, all while the filter continues to function without interruption.

The gravity driven, continuously operating polishing filter uses completely submerged filter media, which gives 100% active filtration area all the time. The outside-to-inside flow through the pile cloth media provides much better depth filtration compared to screens. All internal or submerged components are corrosion-resistant stainless steel or non-metallic materials. For retrofits, the square or rectangular filter plates easily fit into existing basins and require only a low driving force of 30 cm water column.

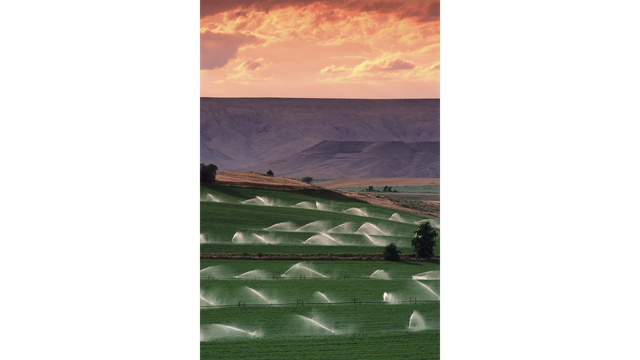

Produce high-purity filtrate from applications such as tertiary filtration, process streams, surface water treatment and other water reuse as you handle solids and hydraulic loading with a small footprint-to-flow ratio.

Як ми можемо допомогти вам?

Вас також може зацікавити ...

Рішення для кругової економіки

Все більше і більше очисних споруд відкривають переваги кругового, цілісного підходу до очищення стічних вод. Заощадження коштів, зменшення впливу на навколишнє середовище та нові надходження доходів від видобутих ресурсів - це лише декілька. Кожна очисна споруда є унікальною і має свої власні проблеми та можливості. Завдяки своєму досвіду в обробці та широкому асортименту продукції ми можемо підтримати ваш перехід до кругового потоку ресурсів. Незалежно від того, ви підрядник, дизайнер або оператор заводу, ми можемо допомогти вам знайти оптимальне рішення для вашого конкретного проекту.