PureNOx

Alfa Laval PureNOx has long been the choice for water treatment in Exhaust Gas Recirculation (EGR), a leading technology for Tier III NOx compliance. Today it’s available in an even more streamlined solution – PureNOx LS (Low Sulphur) – that supports both Tier III NOx compliance and Tier II fuel savings. PureNOx LS is optimized for EGR engines that operate on low-sulphur fuel. Upon request, solutions for use with high-sulphur fuel can also be tailored using PureNOx technology.

The EGR water cleaning solution with most time at sea

- Compact and robust separator with high efficiency

- Designed for continuous operation

- Low operating costs – no filters to replace

- Connectivity-ready and supported 24/7 worldwide

- Compliant with MEPC.307(73) and optionally with MEPC.259(68)

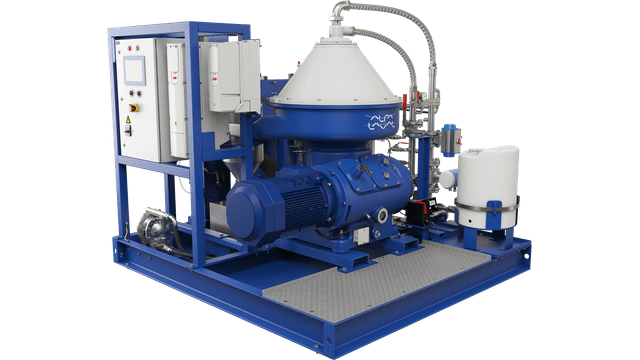

PureNOx LS uses proven and highly efficient separator technology, rather than costly filters or sensitive membranes. PureNOx LS (Low Sulphur), which is optimized for EGR engines that operate on low-sulphur fuel, is available in two sizes. PureNOx LS 50 is for smaller vessels with engines up to 16 MW, while PureNOx LS 100 handles engine capacities up to 60 MW (45 MW on LNG).

Alfa Laval PureNOx: EGR water treatment with a difference

EGR has always been simple, compact and cost-effective but with the latest PureNOx developments, those advantages are even greater. PureNOx systems are now optimized according to the fuel sulphur level: low-sulphur (LS) or high-sulphur (HS).

Reducing NOx emissions from ship exhaust

Alfa Laval PureNOx water treatment system on board ensures full compliance with IMO and VGP regulations for NOx emissions. It also provides you with peace of mind, allowing free movement of your vessel worldwide and easy access to our global service network.

Як це працює

PureNOx LS is designed for use with EGR engines that operate on low-sulphur fuel. In the EGR process, water is used to remove soot particles from the exhaust gas that is recirculated into the engine. This creates a certain amount of condensate, called EGR bleed-off water, that must be cleaned before discharge in accordance with EGR guidelines from the MEPC307(73).

PureNOx LS cleans the EGR bleed-off water by means of centrifugal separation, a method that has proven successful in years of real-life EGR water treatment at sea. Based on experience from years of real-life operation, MAN Energy Solutions has determined that EGR process water cleaning is not necessary when low-sulphur fuel is used. This allows for a PureNOx LS setup that resembles a bilge water system, where the centrifugal separator cleans the water down to a level of 15 ppm oil in water and uses an oil monitor and a three-way valve to verify its cleanliness before discharge overboard.

Unique support for Eco EGR

As well as supporting Tier III NOx compliance, PureNOx LS supports Eco EGR. Eco EGR is a fuel-saving engine mode in which EGR is performed using a smaller amount of exhaust gas (10–15%) during Tier II operation. For EGR engines with Eco EGR capability, the savings are considerable when running on low-sulphur fuels.

Eco EGR allows the engine to be trimmed for maximum fuel efficiency, optimizing specific fuel oil consumption to produce fuel savings of up to 6 g/kWh. However, Eco EGR requires continuous water treatment. PureNOx LS is proven in continuous use, whereas other systems on the market can only operate intermittently. This makes PureNOx LS the only solution on the market that is compatible with Eco EGR.