Alfa Laval Compabloc condenser solved fouling problem

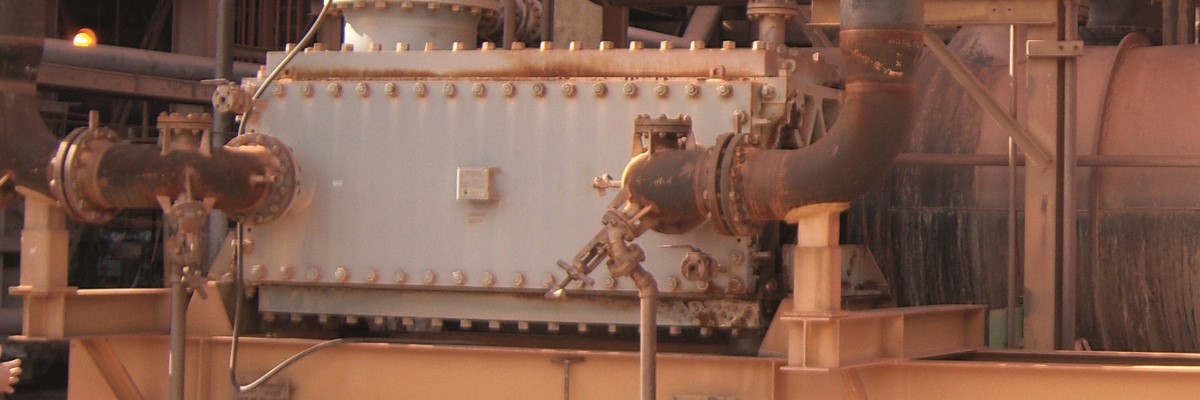

Queensland Alumina replaced a shell-and-tube unit with a fullywelded Alfa Laval Compabloc condenser unit in order to decreasemaintenance costs. Utilising only a quarter of the space of the oldshell-and-tube installation, the Compabloc solved severe corrosionand fouling problems resulting in a significant service cost reduction.

DATE 2023-11-28Process Plant

The Queensland Alumina plant at Gladstone produces 3.7 million tonnes of alumina annually using the Bayer process, the thermal process based on the solubility of alumina in caustic liquor.

Heat exchangers are required for a broad spectrum of duties in the process of heating and cooling the circulating liquor stream. The Compabloc replaced the original carbon steel shell-and-tube heat exchanger in the precipitation area, where it is heating incoming process water with final flash vapour at 29 kPa abs.

The compact, fully welded Compabloc heat exchanger is designed to operate with a wide range of aggressive media and at high temperatures and pressures.

Looking for a new solution

As for many process industries using heat exchangers, the most important requirements for Queensland Alumina are:

- High thermal efficiency

- Low fouling and scaling

- Minimal space requirements

- Design flexibility

- Ease of installation

- Minimal maintenance